Overview

IES were contracted to Indaver Ireland Ltd to design, manufacture and commission a SCADA/PLC based control system for the Blending Plant which is located at Indaver Ireland Ltd, Dublin Port, Dublin 1.

The SCADA/PLC Control System

IES are industry leaders in the installation of SCADA (Supervisory Control And Data Acquisition) systems, the modern solution to monitoring and controlling plant and equipment through the gathering and analysis of real time data.

The Client

Indaver is a Europe-wide waste management company providing services to industries and government authorities. Their solvent blending plant at Dublin Port is licensed to process 20,000 tonnes per year. Instead of being exported for incineration, the facility can recycle the waste into fuel which can be used in various ways including cement production, and can recover valuable raw materials. The energy that is released during treatment is supplied to third parties.

The Challenges

Challenges of particular significance to this project included:

- Compliance – the system must comply with EU regulations for the management of hazardous materials

- Containment – the system must operate in such a way that different materials do not come into contact with each other

- Containment – materials must be restricted to the appropriate container

- Hazardous area – the plant area is classified as a Zone 1 Group IIB T4 hazardous area.1

- ‘Fail Safe’ – because of the hazardous materials being processed, the plant equipment and software controls need to be configured in a ‘fail safe’ mode.

1Zone 1 – Ignitable concentrations of flammable gases or vapours which are likely to occur under normal operating conditions

Group IIB – Atmospheres containing ethylene, or gases and vapours of equivalent hazard

T4 – Hazards which will not ignite at a temperature below 135C

Objectives

IES worked with the client to design and implement a control system which would achieve the following objectives:

- To automate the plant’s loading, unloading, pumping and mixing processes in a safe and controlled manner.

- To provide an effective operator interface to facilitate the manipulation of the different elements of the blending plant.

Hardware

The Control System designed by IES comprises the following hardware:

- The Control Panel, containing the Siemens PLC, located in the safe area. This panel controls the automated sequences, manual operations, interlocks and alarms relating to the Blending Plant.

- A dedicated motor control centre (MCC) for the electrical pumps, located in the safe area.

- A SCADA client PC (InTouch runtime).

- A SCADA server PC (InTouch development).

Programmable Logic Controller (PLC)

The PLC controlling the installation is the SIMATIC S7-300 which has a modular design, allowing for future adaptation. The PLC controls the automated sequences (unloading, loading, pumping and mixing).

The SCADA System

- To comply with the safety requirements and ensure containment, all interfacing between the safe and hazardous areas is via Turck Banner’s ExCom, a modular industrial I/O system specifically designed for hazardous areas.

- The PLC communicates directly with the Turck I/O via a Profibus digital network.

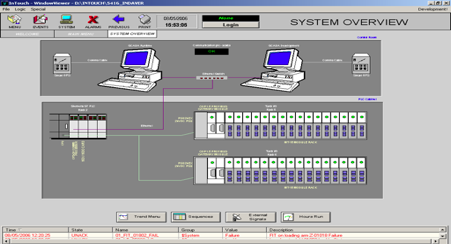

- The system is based on the Wonderware Intouchplatform, an innovative SCADA/Human Machine Interface (HMI), which gives the user an excellent graphic visualisation of the entire process.

- The SCADA and PLC are configured on an Ethernet network.

- The SCADA allows the operator to monitor and control the plant equipment and process sequences via two Intouch Operator stations.

The System in Operation

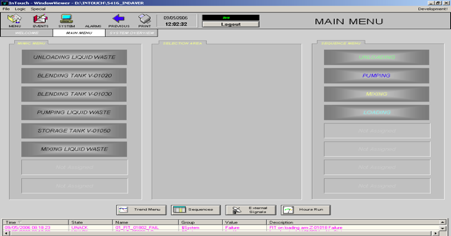

The PLC controls the automated sequences (unloading, loading, pumping and mixing), the manual operations selected by the operator and also the interlocks between the plant equipment. The SCADA allows the operator to monitor and control the plant equipment and process sequences via the two InTouch operator stations.

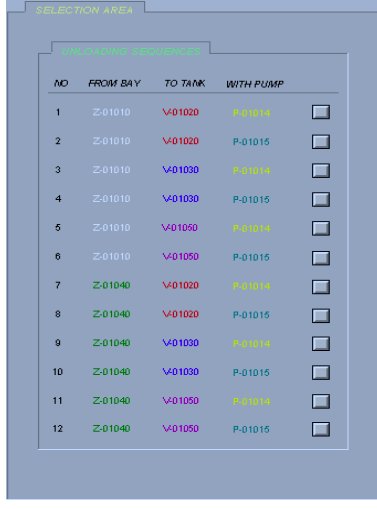

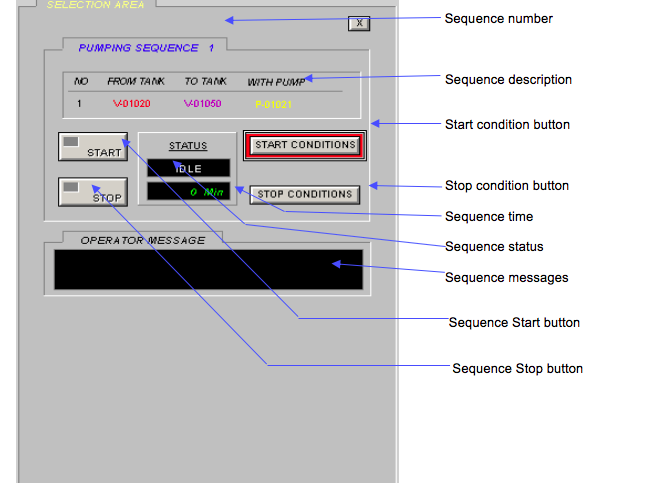

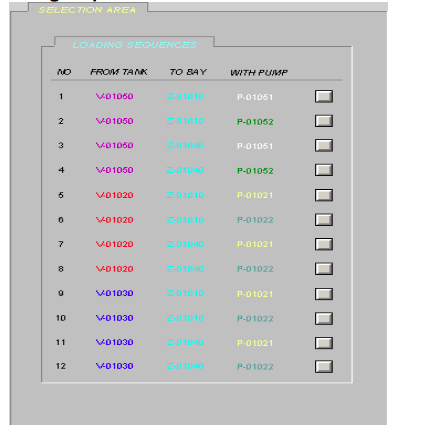

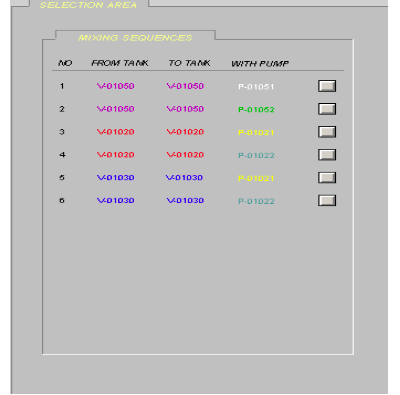

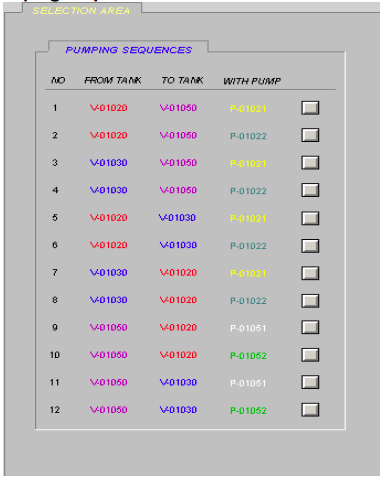

Sequences

In the operation of the process plant the system allows for 42 possible sequences, of four different types: Unloading, Pumping, Mixing and Loading. All sequences have the same structure.

There are three unloading/loading sequence start/stop push button stations located throughout the plant. Each station has two buttons, one to confirm the start of the sequence and the other to stop the sequence.

Outcome

The project concept, detailed design and project management was conducted in-house by Indaver and IES, and was completed on schedule and within budget. Since completion of the original project, IES has been tasked with providing “continuous improvements” to the processing system.

Project Team

- IES Project Manager – Pat O’Sullivan,

- SCADA Software Engineer – Ian Elkington,

- PLC Software Engineer – Miguel Silva,

- Installation & Commissioning Engineers – Ted McCarthy & Leo Seery

Did You Know?

Waste disposal is not a new problem. The ancient world’s biggest rubbish dump is in Rome; a 150ft. mountain of broken and discarded pottery amphorae, which were the oil drums of the Roman Empire. The dump, called Monte Testaccio (from the Latin testa and Italian cocci, both meaning “potsherd”) is almost a mile in circumference.

WALL-E, the waste management robot in the Pixar movie, was modelled on a pair of binoculars (his head) and an ink-jet printer (his body). The film won the 2008 Golden Globe Award for Best Animated Feature Film.

Although the regulation of hazardous waste has become an increasing concern in recent years, it has a long history. The first UK Alkali Act was passed in 1863 to deal with air pollution from alkali works, and it also established a central inspectorate. A subsequent Act of 1874 introduced the concept of ``best practicable means`` to prevent noxious emissions and render them harmless. The Act remained on the statute books until 1996.