Overview

The aim of this project is to Design, Build, Test, Deliver, and Commission the Lime Dosing Control System on behalf of Spiroflow Ltd. The system was designed to allow the safe and efficient sack tipping, transport, storage and dosing of Hydrated Lime into a liquid stream of ‘spent’ Potassium Hydroxide Potassium. Hydroxide is re-circulated from an adjacent large capacity tank. The control system is divided into two systems, the sack tipping and silo fill system and the silo discharge system each with there own PLC. The final location of the control system was in a Zone 2 Eexd IIB T4 harsh environment with low temperatures in Siberia.

Risks & Constraints

The main constraints with this project were mainly around the environment in which the control systems final location would reside. The location in a hazardous area which meant unique and suitable materials and equipment needed to be selected to meet the ATEX directive together with its harsh environment. The control system and associated equipment will meet the Atex Hazardous Area Classification Ex II 2G T4 IIB.

The Strategy

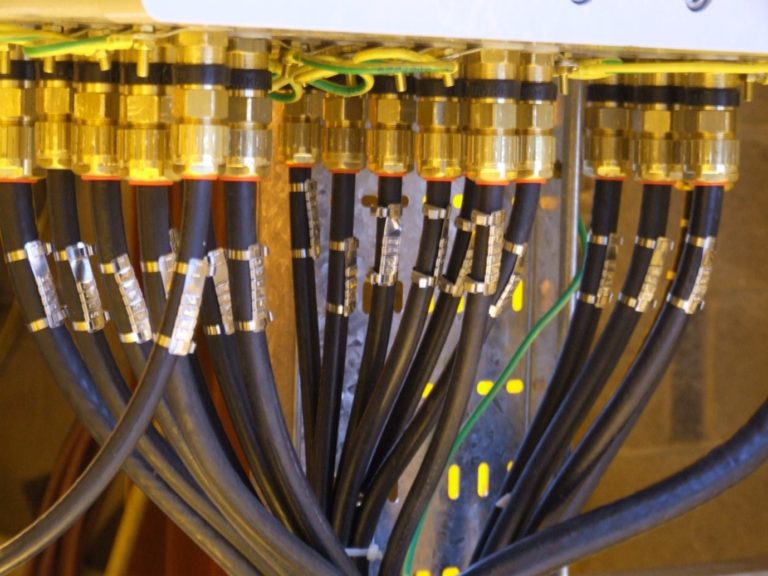

The strategy was supply all the necessary control system hardware and software to to allow the safe and efficient sack tipping, transport, storage and dosing of Hydrated Lime into a liquid stream of ‘spent’ Potassium Hydroxide Potassium in a hazardous environment. This included three main Ex D control panels, cabling, glands, cable containment, emergency lighting, safety systems and all the necessary labour on the Spirfolow premises to full commission the installation before being shipped to the final destination. The innovative design of the system architecture, control panel layout, new The full scope including cabling and electrical connections, had to be done within a challenging timeframe.

Key Objectives and Benefits

The system was able to operate in a Zone 2 Eexd IIB T4 environment and operate between temperatures -40°C to +36°C. The system duty can fill Hydrated Lime at a rate of 4.0m³/hr into a silo capacity of 14.0m³ and silo discharge rate of 0.85 m³/hr – 3.5 m³/hr. The system, using Siemens PLC technology can be operated in both automatic and manual sequence operation. The entire system, compliant to the ATEX directive and supplied and installed with precision accuracy and outstanding quality.

The Design and Implementation Teams

IES provided original concept hardware/software design solutions derived from developing a suitable a best-suited quotation, providing project management and supervision of mechanical and electrical contractors on-site during the installation phase, testing and commissioning. IES also provided an offshore resource to lead final commissioning. Both hardware and software designers and engineers work together at all stages of the design and upgrade and the development to assure that the new system could be implemented as seamlessly as possible.

The Project Team

- Lead Project Manager & Electrical Design – Ross Patrick

- Software & Commissioning Engineer – Shadab Azwar