Overview

IES systems worked in partnership with ASaP (Analytical Solutions and Products BV) to design and implement a PLC (Programmable Logic Controller) for an Advanced Burner Control+ (ABC+) System for Valero.

Valero Energy Corporation

Valero, based in San Antonio, Texas, has a refining throughput capacity of approximately 3.1 million barrels per day, making it the largest independent petroleum refiner in the world.

ASaP (Analytical Solutions and Products BV)

With its headquarters in the Netherlands, ASaP is an international business specialising in process control, product quality control, energy savings and compliance with environmental emission standards and licenses. They have wide experience in providing control systems for refinery operations in the petroleum industry.

– Jacobs Comprimo

Based in The Hague, Jacobs Comprimo Sulphur Solutions specialises in all aspects of sulphur recovery plant design and operations.

The Challenge

From the start of the design process, as even the first project had two very similar subsystems, the PLC & Human Machine Interface (HMI) programming had to be developed in a very structured way. This was necessary to allow for an easy and simple update of code from one system to another, and later from one project to another.

The Strategy

IES has designed control systems for Valero for over 20 years; and Jacobs Comprimo was impressed by their expertise, so IES was the ideal choice for this complex task. IES was introduced to their partners ASaP (Analytical Solutions and Products BV) for the design of the PLC control system for future ABC+ projects.

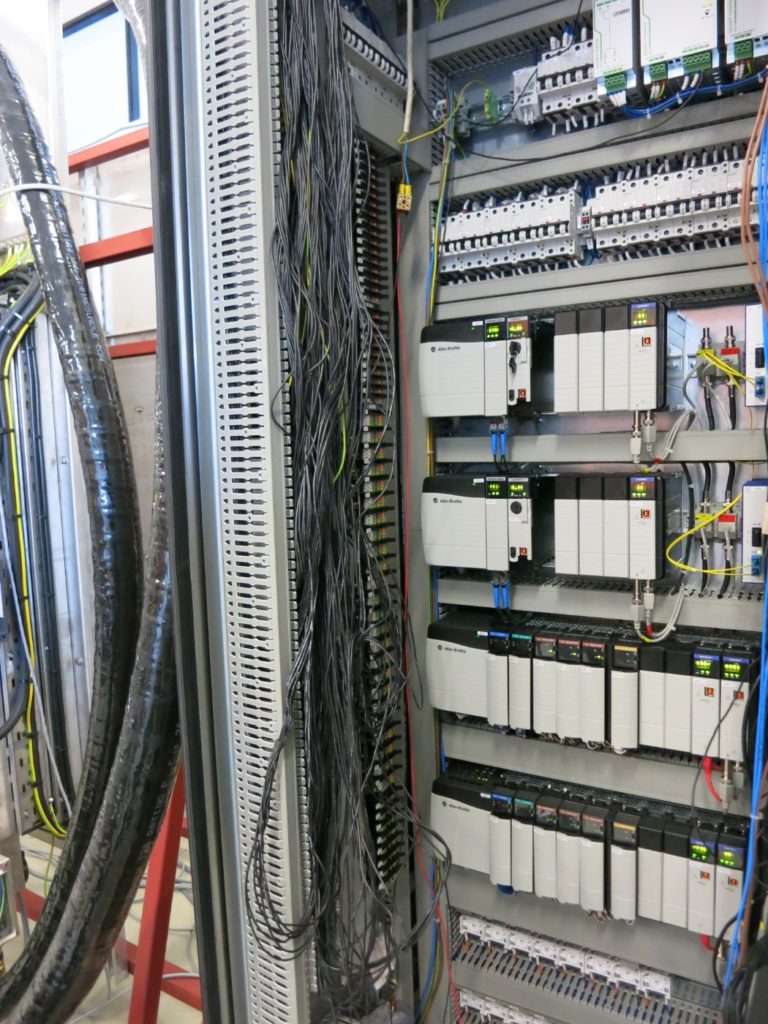

The Advanced Burner Control+ (ABC+) System, designed by this expert partnership, utilises proprietary Jacobs Comprimo algorithms, providing air to feed gas ratio and feed gas mole weights as outputs to be used in the client DCS (distributed control system) for improving sulphur recovery efficiency, as well as producing other benefits.

The Design and Implementation Teams

IES worked with the client and with ASaP to design and implement the PLC for an Advanced Burner Control+ (ABC+) System for the Valero plant.

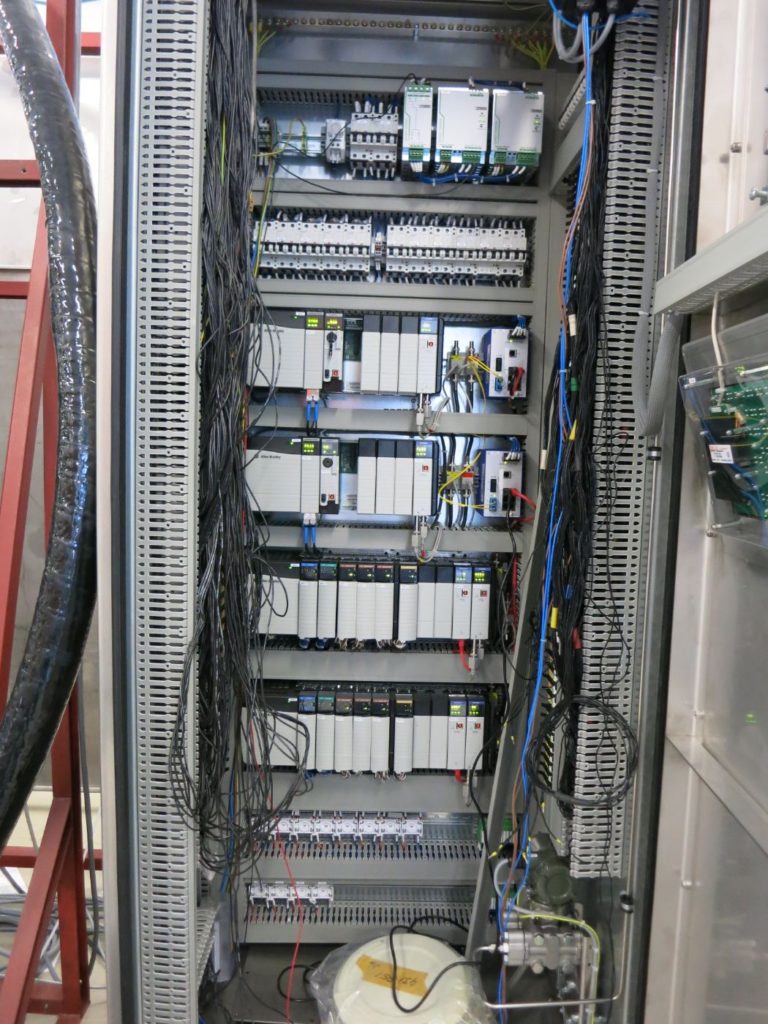

With a control system as complex as this, the software and hardware design team needed to be supplemented by the project management team to coordinate and ensure timely delivery for the different phases of the project.

As an array of local and international consultants, vendors and contractors were involved in this project, a phased approach to testing was necessary, allowing for each subsystem to be individually tested and any defects rectified before the full system came together.

There has been continuous improvement in the design process, reducing the engineering time required for future projects with the development of a standardised design, which is still flexible enough to accommodate client-specific requirements (such as the panel type, communication protocol or additional calculation requirements). With the latest project, the heater controllers have also been implemented in the PLC, and are easily accessible and configurable via the HMI.

The System

The analytical system designed by ASaP analyses Acid Amine Gas (AAG) or Sour Water Stripper Acid Gas (SWAG) and provides the IES PLC Control system with the gas volumetric percentage broken down into individual components2S, (H2S, CO2, H2O, THC and NH3)). Based on these values and the calculated compensated flow, the PLC will calculate the live air-to-gas ratio and mole weight for each gas; these results are transmitted to the DCS for Sulphur Recovery Unit (SRU) burner control.

The system includes the following automated sequences:

- Start / Stop Analysis

- Auto Zero Calibration (for analysers)

- Test Gas Verification (whereby the system can be tested via a temporary test gas bottle connection)

- Maintenance Override (allowing for manual control of valves)

Furthermore, the system is designed to monitor key parameters including H2S detection and will trip to a safe state should an unhealthy condition occur, based on a Cause & Effect (C&E) Matrix.

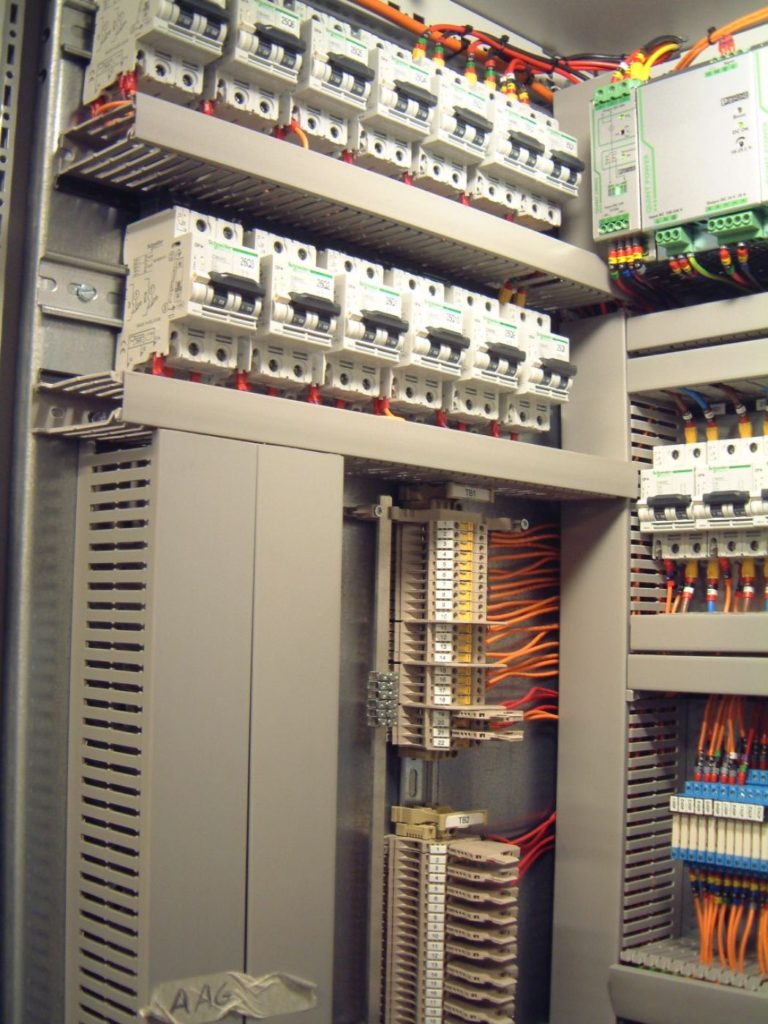

| Project 1 | PLC & HMI: | ControlLogix PLC (1 for AAG, 1 for SWAG, 1 Common HMI) |

| Panel: | Standard Main Panel | |

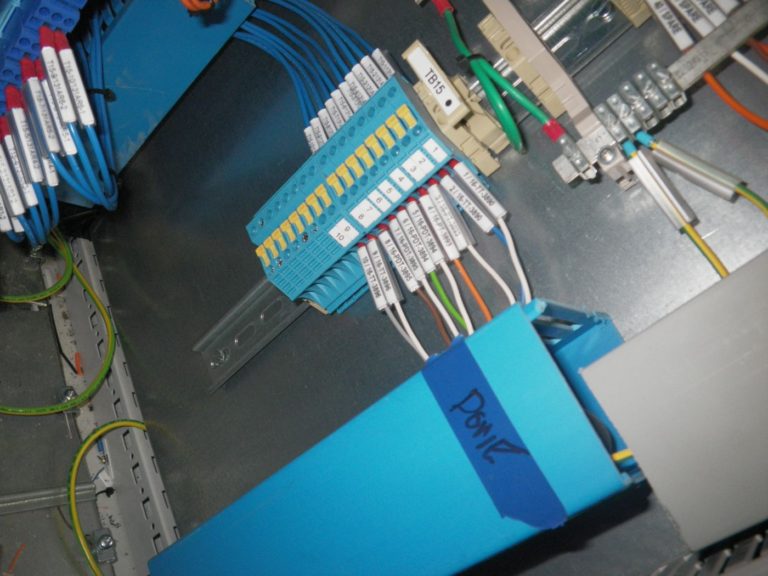

| Field Wiring: | Hardwired via IS barriers from main panel | |

| DCS Link: | 1 x Redundant RS-232 | |

| O2 Enrichment Calc. in PLC: | Yes | |

| No. of Trains: | 2 | |

| Train Delay Calc. | No |

| Project 2 | PLC & HMI: | Redundant ControLogix PLC (1 Pair for AAG & SWAG, 1 Common HMI) |

| Panel: | Ex-p Purged Main Panel in field | |

| Field Wiring: | Hardwired from main panel | |

| DCS Link: | 2 x Redundant RS-232 Link | |

| O2 Enrichment Calc. in PLC: | No | |

| No. of Trains: | 2 | |

| Train Delay Calc. | No |

| Project 3 | PLC & HMI: | ControlLogix PLC (1 for AAG, 1 for SWAG, 1 Common HMI) |

| Panel: | Standard Main Panel (2 x Ex-d Field Panels, 2 x Ex-e Field Panels) | |

| Field Wiring: | ControlNet to Flex IO Cards & then hardwired | |

| DCS Link: | 2 x Redundant RS-485 Link | |

| O2 Enrichment Calc. in PLC: | Yes | |

| No. of Trains: | 2 | |

| Train Delay Calc. | No |

| Project 4 | PLC & HMI: | Redundant ControlLogix PLC (1 Pair for AAG, 1 Pair for SWAG, 1715 IO Cards for DCS, 1 Common HMI, 1 Field HMI for AAG, 1 Field HMI for SWAG) |

| Panel: | 2 x Ex-d Field Panels | |

| Field Wiring: | Ethernet to Flex IO Cards & then hardwired | |

| DCS Link: | 1 x Redundant RS-232 | |

| O2 Enrichment Calc. in PLC: | No | |

| No. of Trains: | 3 | |

| Train Delay Calc. | Yes |

The Outcome

With four different ABC+ systems successfully commissioned and running in different parts of the world, our clients have improved their sulphur recovery efficiency and thereby reduced their emissions.

Valero has the first plant in the world with an ABC+ algorithm residing in the PLC.

The phased testing approach ensured smooth integration, testing and commissioning with reduced downtime and avoidance of unexpected delays.

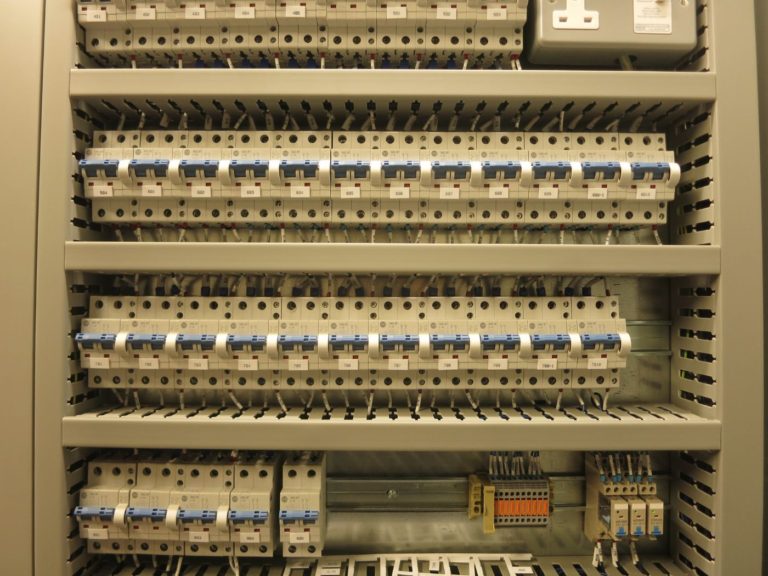

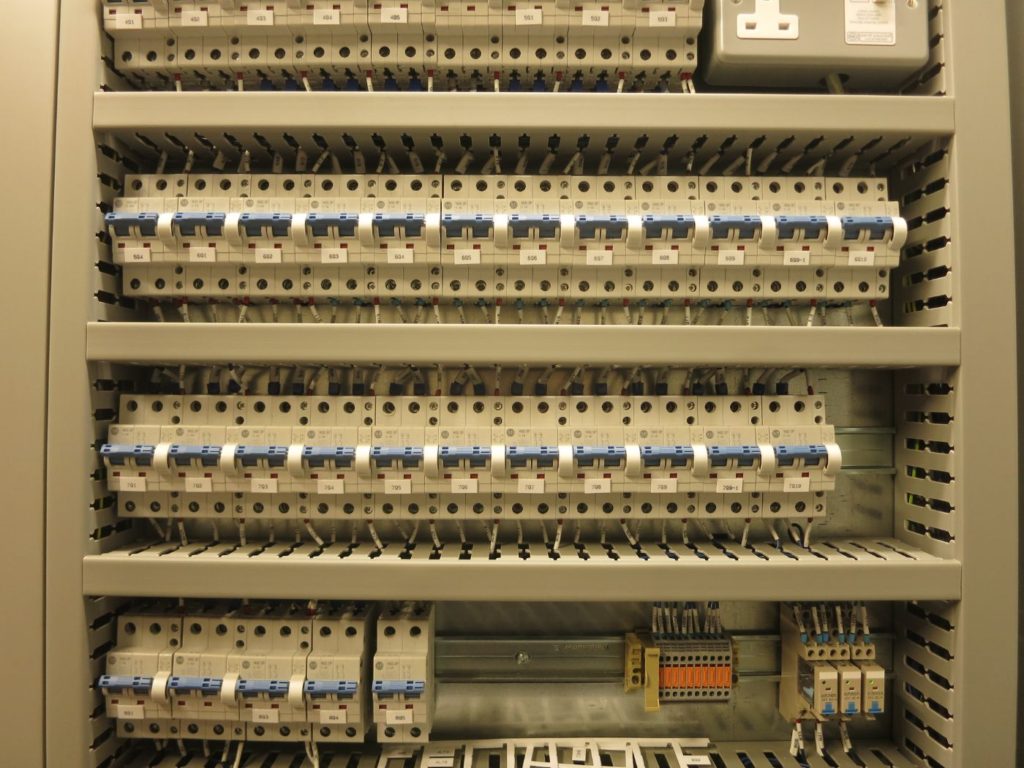

Please find an example of Valero alarms configurable to 30 alarms groups.